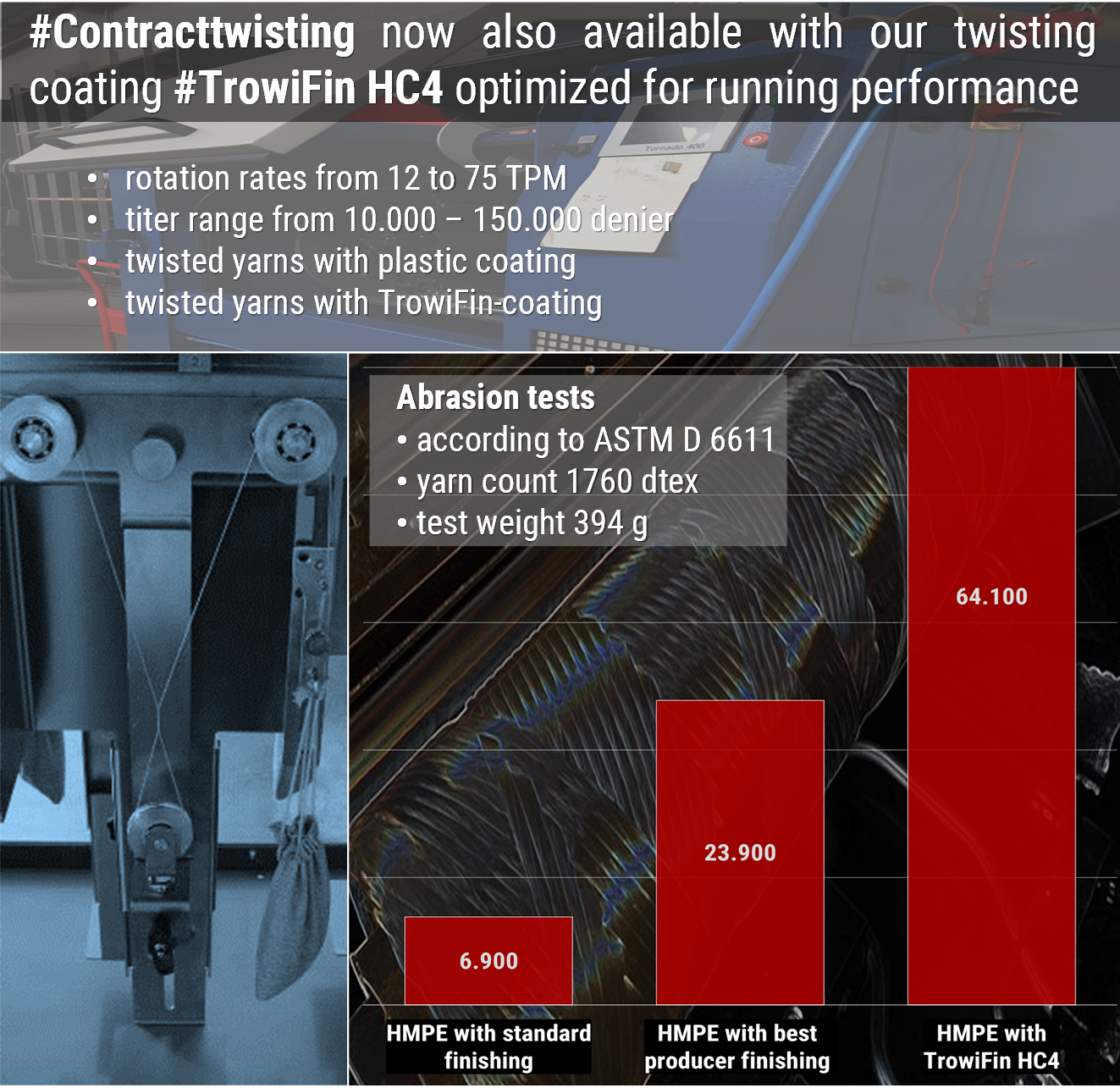

Contract twisting – your twisted yarn in good hands This week we had the opportunity to sample 400 kg of high tenacity twisted yarn for a global textile company. We are very satisfied with the result. The twisted yarn we produced exceeds the required tensile strengths and could be produced with minimal yarn waste.

News

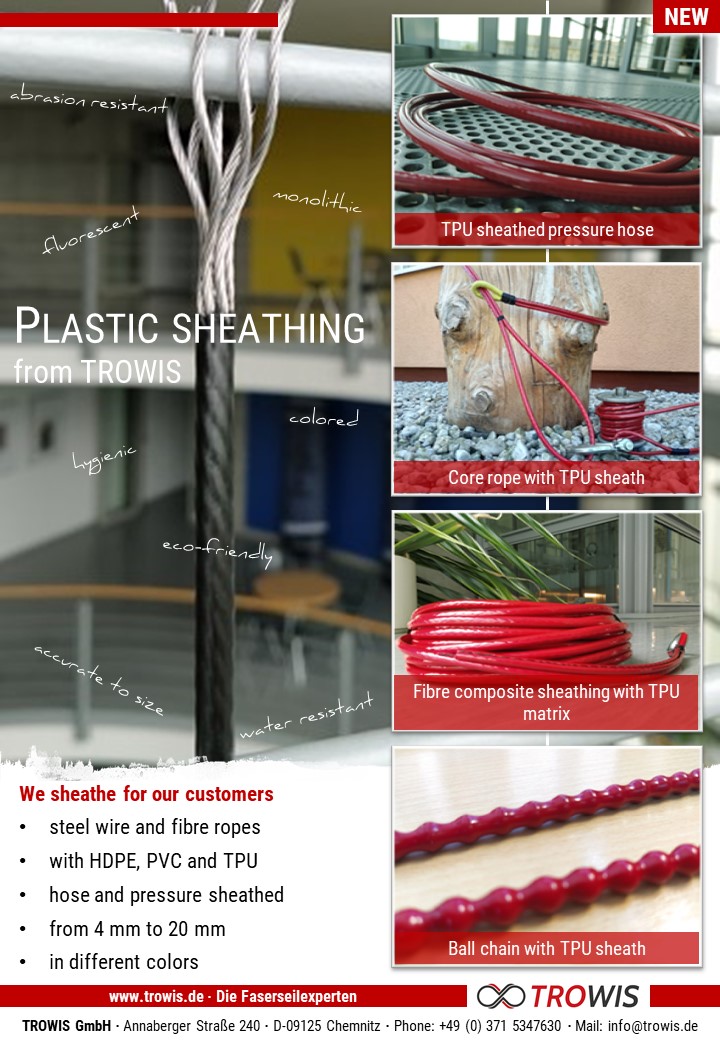

PLASTIC SHEATHING FROM TROWIS

Our PolyTrop FOX rope

At the beginning of last week we produced another 1500 m of our 8 mm PolyTrop FOX. This is a particularly abrasion-resistant all-purpose rope with a braided core rope made of high-strength polyester. The rope has a good grip, is water repellent, hygienic and looks top after every use. Then, last Friday, we tested the …

Read More

Plastic sheathed traction ropes

Last week we delivered traction ropes for handling technology. The ropes are equipped with a red protective sheath and for the first time with sewn rope loops. In handling areas, ropes are used, for example, as unlocking, braking and trapping ropes. The red plastic sheath makes the operating elements easy to identify. In addition, they …

Read More

TrowiFin-rope coating

When it comes to durability and service life, rope coating is absolutely essential. However, fibre coatings from rope producers are often not sufficient and even a post coating of the entire rope does not lead to optimal results – due to a lack of rope penetration. With our developed TrowiFin coatings and our twisting service, …

Read More

Yarn abrasion test at TROWIS

Our re-usable bobbin for ropes

Do you know this too? You are winding ropes on a plastic bobbin and “crack” – the pressure on the flanks has caused the bobbin to burst and your beautiful, new rope lies on the ground and can only be wound up again with great effort. We have the alternative to the plastic single-use bobbin. …

Read More

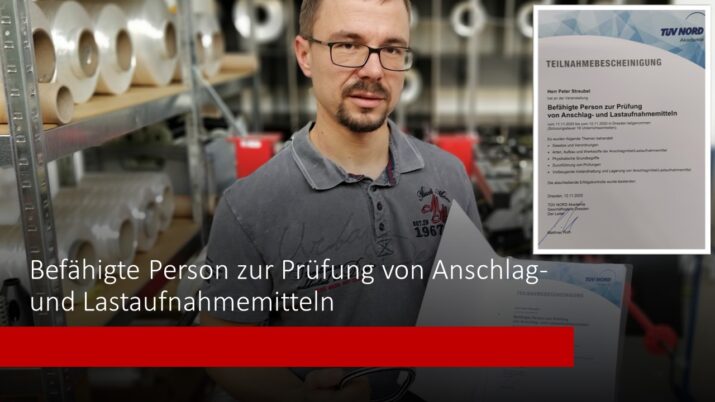

Testing of slinging and load handling equipment

Wherever loads are lifted or moved for transport, slings and load handling equipment are used. Whether sling rope, rope sling, lifting strap or round steel chain – all these slings are relevant to safety and must be subjected to regular inspections. Our technical managing director, Mr. Peter Streubel, has successfully participated in the seminar: “Qualified …

Read More

Trowis on the Innotrac

The first international traction mechanism colloquium innoTRAC is being held virtually on 12 and 13 November 2020. This event brings together the GKT Symposium on plastic slide chains and tribology in traction and load-bearing mechanisms and the technical colloquium InnoZug organized by the chair of Conveying Engineering and Materials Handling at the Technische Universität Chemnitz. …

Read More

The ROBLON Tornado 400: our latest investment!

The bigger version of the T300 is a high-performance twisting machine to produce rope yarns for ropes, round slings, and non-crimp fabrics. This machine, which was delivered at the end of September 2020, is another TROWIS investment into its state-of the-art equipment to manufacture fiber ropes for traction and load-bearing applications. After a three-week test …

Read More