-

Trowis GmbH

We employ high-strength plastic fibres in place of steel.

-

Trowis GmbH

High-performance fibre materials provide totally new design options for running ropes. Combining these materials with the latest manufacturing technology gives you the perfect rope.

-

Trowis GmbH

We at TROWIS produce ropes for cranes, lifts, elevators, and winches as well.

At the TROWIS GmbH, we produce ropes for cranes, elevators, and winches. What makes our ropes unique is the material they are made from. We use high strength plastic fibres instead of steel wire ropes. These fibres offer a wholly new scope for design for running ropes. Add state-of-the-art production technology, and the result is the perfect rope.

TROWIS ropes are designed as a self-monitoring fibre composite that warns the user in advance when it is time to remove it from service. This gives TROWIS ropes the highest operational reliability.

TROWIS ropes are up to 80 % lighter than commensurable means of suspension. This not only ensures better handling during installation, but also makes greater lifting heights possible.

The initial elongation of TROWIS ropes is up to 85 % less than that of conventional fibre ropes. In other words: when you use TROWIS ropes, there is no preloading to stretch required. Put the rope on and get to work.

In comparison with conventional ropes of identical diameter, TROWIS ropes are also up to 40 % better in terms of load capacity. This, in turn, means less rope is needed per machine or larger net loads.

Finally, TROWIS ropes last up to 7 times longer than conventional ropes. This contributes to both lower maintenance and repair costs and greater equipment reliability.

Successful twisted yarn sampling of 400 kg

20. September 2021

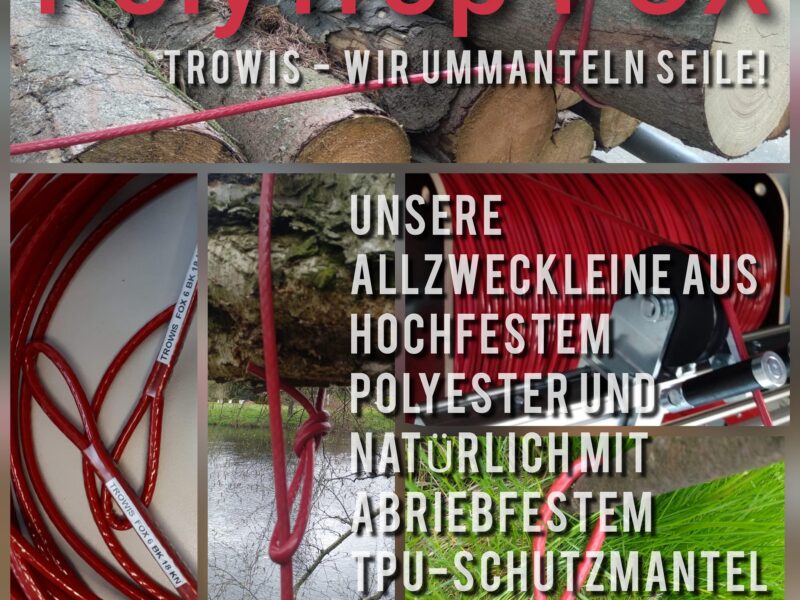

PLASTIC SHEATHING FROM TROWIS

21. July 2021

Our PolyTrop FOX rope

26. May 2021Safety and reliability are central to our efforts to supply high strength fibre ropes for lifts and elevators.

Lighter, much lighter. Lightweight design is the basis for new technical solutions in rope design - the main advantage our ropes have over classic steel ropes is their substantially lower weight.

- up to 80 % less weight

- minimal initial elongation thanks to our TEXELMA finishing

- highest operational reliability due to self-monitoring rope design

- greatest loading capacity provided by high-performance fibre materials

- maximal service life thanks to high-performance lubricants

- optimal lubricant distribution due to innovative coating method

- application-oriented rope finishing

Question: Your ropes are impregnated with special lubricants to increase their service life. How do you guarantee that there is no slippage between your well-lubricated core rope and the fibre that surrounds the core?

Answer: Our innovative TEXELMA coating technique makes sure that the lubricant is only deposited where it is needed. This not only provides a slippage-free core/ casing bond, but also precludes gas emissions from coating components that can result in defects in the case of thin-walled extrusion layers.

Question: Core ropes with fibre casing, in particular ropes with extruded plastic layers, act as thermal insulators. How do you thermofix your ropes, and why?

Answer: Using the TEXELMA technology, our ropes can be thermofixed through the whole cross section – regardless of the rope diameter – in less than 2 minutes. Thermofixing causes the molecular chains to be newly aligned, thereby increasing tensile strength by approx. 30 % and reducing the initial elongation by approx. 85 %. Initial elongation of our ropes is so minimal that it is not necessary to reel in TROWIS ropes; they can just be used after they are put in place.

Question: How do you design the rope’s-end-to-end connections?

Answer: Thanks to high transverse strength and abrasion resistance, classic wire rope solutions, such as gibs and cotters, disks, and U clamps, can be used. Press sleeves are not useful due to relaxation effects. Non-sheathed ropes are fitted with traditional eye splices.

„We at TROWIS produce ropes for cranes, lifts, elevators, and winches as well.“

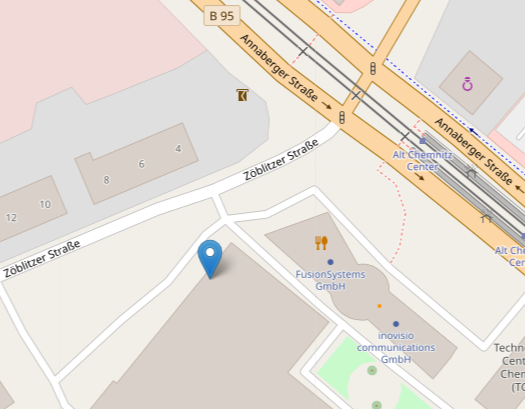

Annaberger Straße 240

09125 Chemnitz

Germany

Phone: +49 (0)371 5347630

E-Mail: info@trowis.de

Information regarding data protection is provided separately. data protection.