The unwinding of yarns and strands via bobbin creel is one of the most underestimated procedures in yarn preparation. During unwinding, the semi-finished or finished textile product’s properties are determined to a large extent. The yarn unwinding tensions must be neither too low nor too high, and, above all, they must not differ from one another. Even if all yarn unwinding tensions are set optimally, the unwinding process will not necessarily be successful.

The unwinding method primarily used is known as over-end unwinding: the bobbin is fixed in its location, and the thread is unwound along the bobbin axis (over-end). Since the bobbin is stationary and no inertia of masses must be overcome, the threads can be unwound at very high speed. However, with each winding pulled off from the bobbin this way, another twist (traverse pitch) is added to the yarn, or, as a function of the direction (s- or z- twist), it is diminished by one twist. In the case of thick, high-modulus strands, this forced twisting can result in tremendous strength losses, and, more importantly, heterogeneous elongation characteristics across the textile’s length.

To overcome this issue, particularly when folding and rewinding rope strands, tangential unwinding should be used. When unwinding is done this way, no twists are forced; however, it is necessary to reduce the speed of the moving bobbins while stopping to avoid uncontrolled unwinding. The classic belt brakes introducing a constant braking moment into the bobbin cause – as a function of diminishing bobbin volume – the unwinding forces to become higher and higher; consequently, they are not suitable for precise tangential unwinding. Decelerated bobbins that provide almost constant unwinding forces, are based, as a rule, on servo-pneumatic or electro-mechanical systems and are thus very expensive.

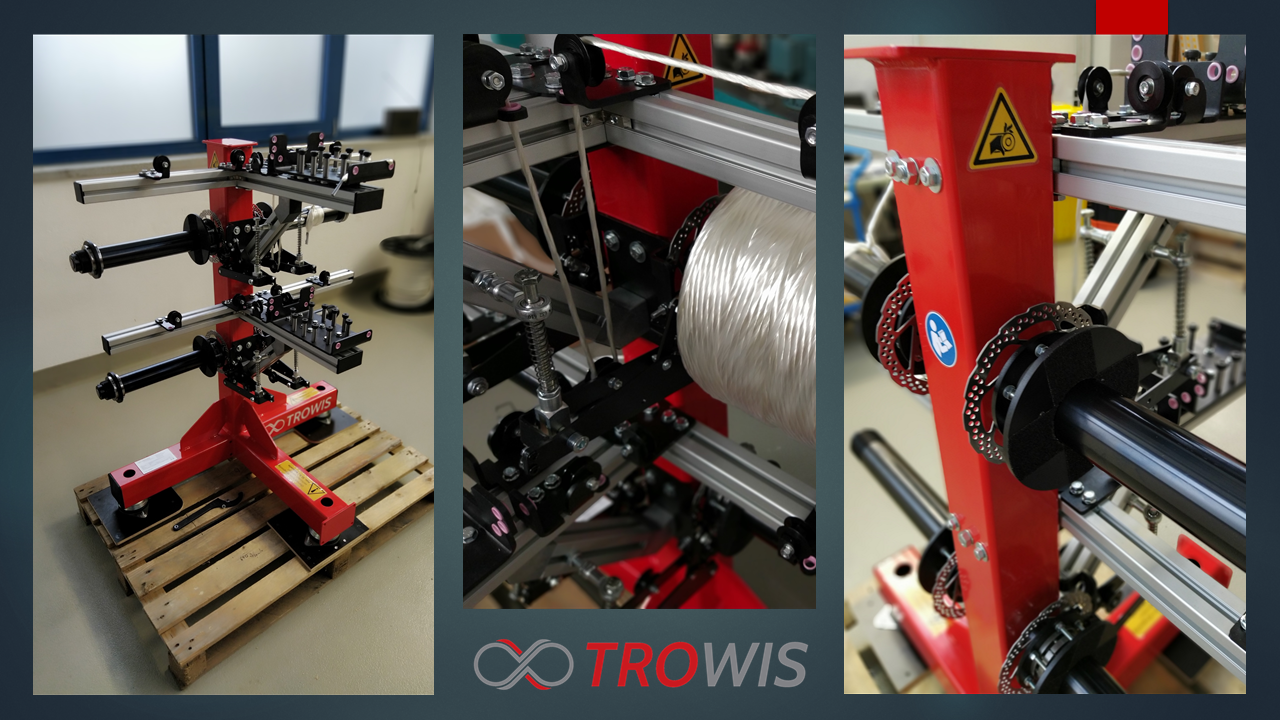

For this reason, TROWIS has developed, designed, and built a bobbin creel with mechanical tenser control, consisting of a cantilever brake and a spring-loaded tenser. In this working principle, the unwinding thread defines the braking power at the bobbin and enables – even at unwinding speeds of more than 100m/min – precise adjustment of the yarn unwinding force, as well as a bobbin coasting of less than one meter.

We currently use two basic modules in the laboratory, each with 4 winding heads for flexible uptake of galan, braided, and board bobbins. Extension modules with 4 additional working heads that can be directly placed onto the basic modules have already been planned and will be installed soon.